https://reliablesoftech.com/wp-content/uploads/2025/05/Untitled-design-19.jpg

684

845

Niymat

https://reliablesoftech.com/wp-content/uploads/2020/11/rstlogo-new-300x82.png

Niymat2025-05-26 12:31:282025-05-26 12:40:01Integrating Packhouse Automation with Gamma Irradiation: A Comprehensive Approach to Post-Harvest Processing

https://reliablesoftech.com/wp-content/uploads/2025/05/Untitled-design-19.jpg

684

845

Niymat

https://reliablesoftech.com/wp-content/uploads/2020/11/rstlogo-new-300x82.png

Niymat2025-05-26 12:31:282025-05-26 12:40:01Integrating Packhouse Automation with Gamma Irradiation: A Comprehensive Approach to Post-Harvest ProcessingSmarter Packhouse & Gamma Irradiation Management — From Gate to Export

At Reliable Software Technology, we built this solution by working directly with Packhouse teams — observing how fruit intake, inspections, and certifications were still managed manually, often causing delays and confusion.

What the industry needed was clear: a connected, real-time platform to streamline post-harvest processing, Gamma Irradiation, vendor visibility, and export compliance.

We responded with a fully integrated, cloud-based and AI-powered system that brings every stage — from slot booking to certification — into one seamless digital workflow.

What the Platform Delivers

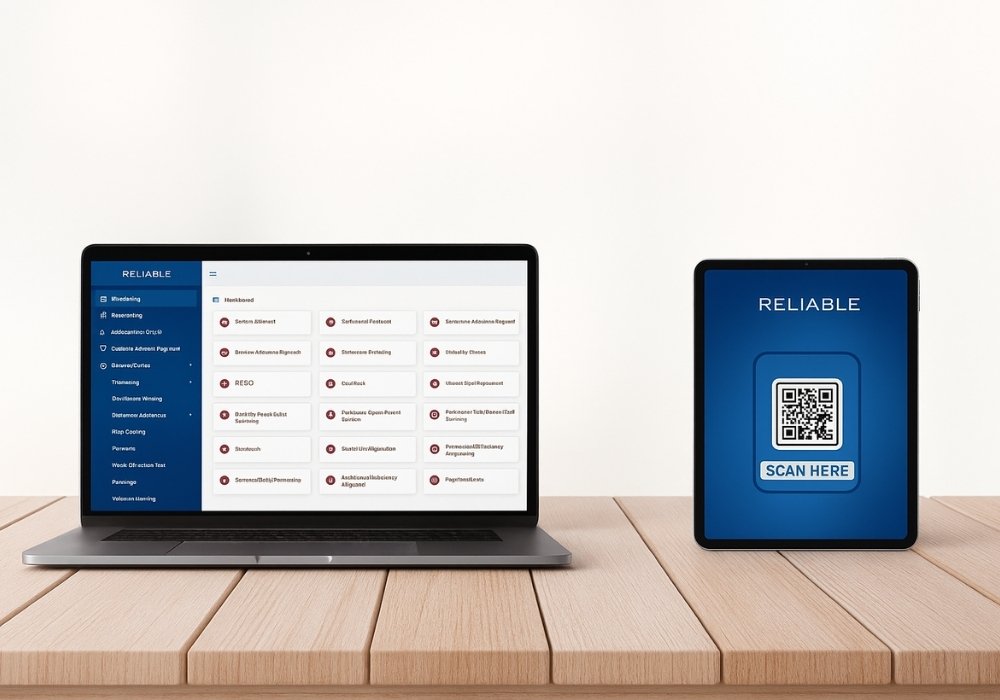

This cloud-powered platform is built to streamline how Packhouses and agro-export facilities operate — with faster processing, end-to-end traceability, and complete control from gate entry to export. Vendors can register online, book appointment-based slots, and track their produce in real time using QR-enabled workflows.

Ideal for post-harvest centers in India, the UAE, Saudi Arabia, and other global agri-export hubs, the solution works seamlessly across web and tablet devices. It’s hosted securely on Microsoft Azure, ensuring high performance, data protection, and easy access across single or multi-location setups.

Whether you’re managing a local Packhouse or running a multi-country export operation, the system scales to your business — bringing clarity, compliance, and confidence to every stage.

Trusted by leading Packhouses across India and the Gulf

What Sets This Product Apart

This platform was developed after deeply studying the real workflows inside Packhouses and Gamma Irradiation centers. We saw delays, disconnection, and lack of real-time visibility across fruit intake, treatment, quality checks, and certification. Vendors had no live tracking, supervisors used paper-based logs, and export readiness often relied on guesswork.

We built this cloud-based, AI-enabled system to solve all of that — providing end-to-end automation, QR-based traceability, real-time dashboards, and secure role-based access. It’s not just software — it’s a full-stack solution for modern, export-focused post-harvest management.

A complete digital workflow for Packhouse automation and Gamma Irradiation — from booking to dispatch.

Experience the Demo in Action See how our platform transforms Packhouse and Gamma Irradiation workflows

Here’s how the platform streamlines your Packhouse and irradiation operations

Vendor Slot Booking

Vendors can register and book slots online by selecting the product type, quantity, vehicle details, and purpose. A QR-enabled gate pass is generated instantly for smooth entry.

Security Management

Security personnel use tablets to scan the vendor’s QR code, log vehicle details, capture vehicle images, and confirm entry/exit — all synced instantly to the cloud dashboard.

Tablet-Based Operations

Supervisors scan crate QR tags and record every treatment stage, including unloading, hot water treatment, ripening, metal detection, packaging, and final certification.

Exporter Dashboards

Vendors get access to their own dashboard to track lot status, view QC results, download treatment certificates, and monitor booking and payment history in real time.

Admin Dashboard

Managers can view live operational metrics, slot utilization, treatment efficiency, export readiness, and receive AI-based recommendations to improve performance.

Access Control

Each team member gets access based on their role. Permissions are fully configurable, ensuring secure, structured control over every module and user activity.

Cloud Infrastructure & Scalability

Built on Azure Cloud, the platform offers secure data storage, real-time syncing, remote access, and the ability to scale the system seamlessly from a single unit to multiple locations.

Automated Certificate Generation

The system generates export and treatment certificates automatically upon process completion, reducing paperwork and ensuring quick, audit-ready documentation for every lot.

End-to-End Order Traceability

From entry to final dispatch, every step is time-stamped, QR-tracked, and centrally stored — ensuring complete traceability for compliance, vendor visibility, and reporting.

FREQUENTLY ASKED QUESTIONS?

What is the Packhouse Automation Platform used for?

Our platform digitizes the entire post-harvest process — from vendor slot booking and gate entry to crate scanning, fruit treatment, certification, and export dispatch. It’s ideal for agro-export businesses, Packhouses, and fruit processing centers.

Is the software only for mango processing?

No. While it was initially tailored for mangoes, it fully supports other fruits (grapes, citrus, pomegranate), vegetables, leafy greens, and herbs. Thanks to our dynamic workflow engine, it adapts to any post-harvest product lifecycle.

Does it support multi-location Packhouse operations?

Yes. The system is cloud-based and built for scalability, allowing you to manage multiple Packhouses or Gamma Irradiation centers through a centralized dashboard with real-time data syncing.

Can vendors book slots and track their produce online?

Absolutely. Vendors can register via the web app, select available appointment slots, pay token fees online, and receive QR-enabled gate passes. They can also track the treatment status of their produce and download digital certificates.

How does the system improve traceability and compliance?

Each crate is tagged with a QR code, and every treatment stage is logged digitally — from hot water treatment and ripening to packaging and Gamma Irradiation. This ensures full traceability, audit readiness, and compliance with agri-export regulations.